- omirri2003@rediffmail.com

- +91-281-2223725

Products › Hydrocyclone Filter

Applications

Used in micro irrigation systems to remove sand and silt particles from irrigation water.

Features and Specifications

- Mild steel construction.

- Coated with more than 70 micron thick deep blue coloured epoxy powder from both inside and outside surface for protection against corrosion and weather effects.

- Hydrodynamically designed to create maximum centrifugal action to separate particles heavier than water

- Efficiently removes fine sand and silt particles of size higher than 75 microns and specific gravity more than 2.65.

- Special protection plate are provided at the bottom of the cone to prevent wearing.

- Large volume of dirt collection chamber increases flushing interval.

- Dirt can be easily flushed out through dirt collection chamber.

- Available in maximum operating pressure of 10 kg/cm² (142 psi).

- Standard end connections are BSP flanged. Please specify for other end connections. (ANSI flanged or Easy-Fix™).

- Recommended to install before media/screen filters to remove particles heavier than water.

- Improves operational efficiency & life of media / screen filters.

- Can also be supplied in stainless steel as a special order.

- Can be supplied in higher flow capacities in multiple batteries option.

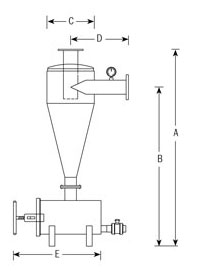

| Nominal Flow Rate |

Inlet / Outlet Connection |

A | B | C | D | E | Vol. of Collection Chamber |

Gross Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|

| m³/hr | gpm | inch | mm | mm | mm | mm | mm | ltrs. | kg. | lbs. |

| 25 | 110 | 2" | 1065 | 865 | 204 | 198 | 460 | 5 | 36 | 79.2 |

| 40 | 176 | 2½" | 1365 | 1112 | 264 | 258 | 520 | 10 | 48 | 105.6 |

| 50 | 220 | 3" | 1575 | 1350 | 323 | 317 | 520 | 10 | 60 | 132.0 |

| 80 | 352 | 4" | 1950 | 1745 | 402 | 396 | 500 | 49 | 89 | 195.8 |

| 120 | 528 | 6" | 2850 | 2275 | 600 | 594 | 500 | 78 | 151 | 332.2 |

* For detailed code please refer the ordering specifications.